Chemical Resistant Urethane (CRU) Resintech

TECHNICAL DATA

CRU is a two-component, abrasion-, chemical-, and stain-resistant, UV-stable aliphatic polyester polyurethane finish coat. It is available in clear gloss, clear satin, and can be pigmented. It is VOC compliant in all states and provinces in North America.

This urethane can be installed at thicknesses ranging from 5 to 20 mils, making it highly versatile for a wide range of applications. It can also be used as a top coat over flake floor systems, serving as a durable alternative to polyaspartic. Unlike polyaspartic, CRU offers more working time and increased durability, making it ideal for installers seeking both performance and flexibility.

CRU cures to an inert, tough, impact-, abrasion-, and chemical-resistant finish. It resists Skydrol, Betadine, and conventional hot-tire staining and provides excellent adhesion to the TUE epoxy system. When applied to properly prepared concrete or cementitious overlays, it requires a Polyurethane-Acrylic Primer and Concrete Sealer for optimal performance.

It is widely used as an upgraded finish coat in Canopus coating systems for:

- Aircraft hangars

- Industrial kitchens

- Automotive showrooms and shop floors

- Commercial laboratories and research facilities

- Hospitals and healthcare environments

- Wine and spirit processing facilities

- Any surface exposed to heavy foot traffic, forklift movement, or chemical exposure

ADVANTAGES

- Long pot life

- Respectable odor

- Superior chemical resistance

- Excellent UV stability and gloss retention

- VOC compliant

WHERE TO USE

- UV-stable top coat

- Aircraft hangar floors

- Production areas

- Maintenance facilities

- Warehouses

IMPORTANT NOTE: PROPERTIES @ 73°F (23 °C) and 50% R.H. Times are approximate and will be affected by changing ambient conditions, especially changes in temperature and relative humidity. The indicated mileage is calculated for flat surfaces. A porous or imperfect surface will require more material in order to cover the same mileage.

| PACKAGING | 1.6 US gal (6 L) |

| COVERAGE RATE | 800 ft2/kit |

| RECOMMENDED THICKNESS | 3.2 wet mils (81 microns) |

| MIX RATIO, BY VOLUME | A:B = 2:1 + .4 lb Aluminum Oxide |

| DENSITY (KG/L) | Part A: 4L Part B: 2L Mixed: 6.4 L |

| POT LIFE | 60 minutes @ 77°F (25°C) |

| WORKING TIME | 30 minutes |

| VOC | 75.4 g/L |

Have Questions? Ask An Expert

Related Products

From this Collection

-

ResinTech UV Resistant TRANSPARENT UNIVERSAL EPOXY 100% SOLIDS (TUE) 15L - 4 Gals$325.00ResinTech TUE (Transparent Universal Epoxy) Specification Product Overview: ResinTech TUE (Transp...

-

ResinTech High Performance Polyaspartic ( HPP ) 10 L / 2.64 Gal$340.00Product DESCRIPTION HPP is a fast-curing, two-component Polyaspartic floor coating system engine...

-

Metallic Epoxy Pigments$49.99Metallic Epoxy Pigments metallic collection 🔹AppleGreen🔸AztecGold🔹BlackPearl🔸Bronze-Brown...

-

Tremco Vulkem 350NF Base Coat$398.00Single-Component, Low Odour, Low VOC, Urethane Membrane Vulkem® 350NF Base Coat is a single-com...

-

Aliphatic Top Coat Urethane (TCU) Resintech ( Satin / Matte Finish )$325.00TCU is a two-component abrasion, chemical and stain resistant, UV stable aliphatic polyeste...

-

Vulkem 346 Top Coat Aliphatic one-component polyurethane$430.00Vulkem 346 Top Coat is an aliphatic one-component polyurethane that is applied after the Vulkem ...

-

Tremco Vulkem 950NF Top Coat$424.00Vulkem 950NF Top Coat is a two-component polyurethane that is applied after the Vulkem 350NF bas...

-

Cup wheel for concrete$134.00Cup Wheel Diamond Disk 7 and 5 inch 6 Arrow segments 15mm height 30 grit soft bond Central...

-

MAPECRETE HARD LI$358.00MAPECRETE HARD LI Lithium Silicate Densifier and Sealer for Concrete Mapecrete Hard LI is a wa...

-

Sika Loadflex-524 EZ technologically advanced, two-component, quick-setting, semi-rigid, solvent-free$69.00Sika® Loadflex®-524 EZ is a technologically advanced, two-component, quick-setting, semi-rigid, ...

-

Vulkem 360NF Base Coat - Low VOC, water-cured, rapid setting urethane membrane$480.00Vulkem 360NF Base Coat is a low odor, low VOC, water-cured, rapid setting urethane membrane that...

-

ResinTech Core Bond EPOXY (CBE) 100% SOLIDS 15L - 4 Gals$325.00ResinTech Core Bond EPOXY 100% SOLIDS (CBE) Specification Product Overview ResinTech Core Bond ...

-

Sika® Level-01 Primer CA one-component, water-dispersed, solvent-free, acrylic-based solution used to prime$48.99Sika® Level-01 PrimerCA is a one-component, water-dispersed, solvent-free, acrylic-based solutio...

-

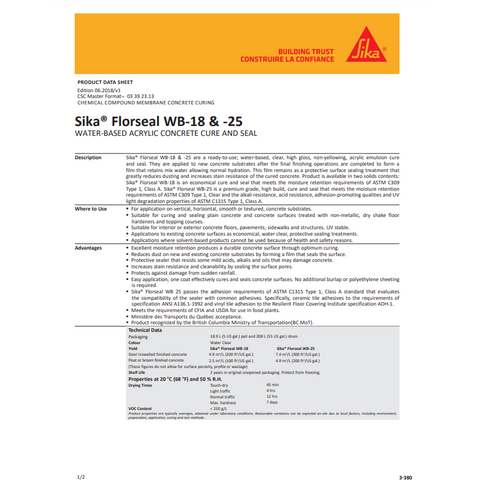

Sika® Florseal WB-18 & -25 ready-to-use; water-based, clear, high gloss, non-yellowing, acrylic emulsion cure and seal$255.00Sika® Florseal WB-18 & -25 are a ready-to-use; water-based, clear, high gloss, non-yellowing...

-

Vulkem 191 QD Primer$390.00Vulkem 191 QD Primer PRODUCT DESCRIPTION Vulkem 191 QD Primer is a quick-drying, one-part,...

-

TREMdri 160$250.00TREMdri 160 Single-Component Asphalt Emulsion Waterproofing Membrane TREMdri 160 is a flexible ...

-

B-TUFF® 5600 4.5-gallon kit A Two Component, Solvent Free, Vehicular and Pedestrian Traffic Deck Coating$650.00B-TUFF® 5600 4.5-gallon kit A Two Component, Solvent Free, Vehicular and Pedestrian Traffic Deck...

-

Mapei Ultratop PC – 50LB Bag$65.50Mapei Ultratop PC – 50LB Bag DESCRIPTION : Ultratop PC is a polishable, self-leveling, cement...

-

MAPEI PLANISEAL WR 100 Clear, (5 Gals) 100%-Silane, Penetrating Water Repellen$495.00PLANISEAL WR 100 Clear, 100%-Silane, Penetrating Water Repellent Planiseal WR 100 is a clear, h...

-

Tremco Vulkem 951NF Top Coat$650.00Product Description Vulkem 951NF Top Coat is an aliphatic, low VOC, two-component polyurethane, ...

-

Eco-MPE™ Multi-Purpose Epoxy$300.00Tennant’s Eco-MPE (Multi-Purpose Epoxy), is a low-odor, 100% solids epoxy that self-levels for ...

-

P-TUFF® CLASSIC$350.00P-TUFF® CLASSIC TECHNICAL DATA SHEET SECTION 3.2.3 A Single Component, Water-Catalyzed Base Memb...

-

PRIMER SN - 3 GAL$598.00Two-Component, Filled, Epoxy PrimerPrimer SN is a two-component, filled, epoxy primer specifical...

-

ResinTech PPM-SL Semi Self-Leveling$20.00ResinTech PPM-SL is a semi self-leveling polymer repair and waterproofing sealant designed for fi...

-

ResinTech Protective Polymer Membrane (PPM) 10L$320.00ResinTech Protective Polymer Membrane (PPM) Single-Component Waterproofing & Protective Coati...

-

Sikalastic® Vehicular Traffic ( Masterseal 1500: Traffic Coating System)$398.00POLYURETHANE BASE COAT FOR SIKALASTIC® TRAFFIC 1500 AND 2000 LOW VOC DECK COATING SYSTEMS (Master...

-

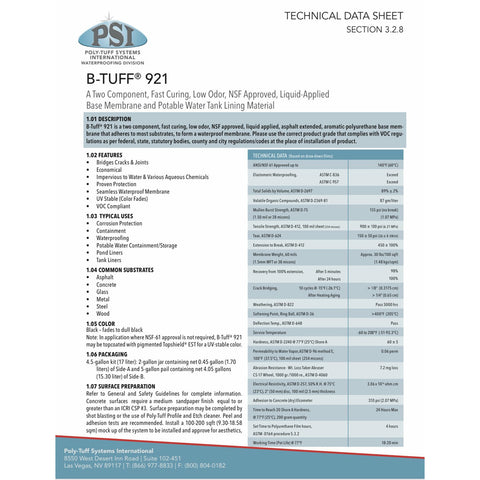

B-TUFF® 921 A Two Component, Fast Curing, Low Odor, NSF Approved, Liquid-Applied$590.00B-TUFF® 921 A Two Component, Fast Curing, Low Odor, NSF Approved, Liquid-Applied FEATURES Bridg...

-

Eco-Crete SL is a self-leveling polyurethane concrete$1,100.00Eco-Crete™ SL Tennant’s Eco-Crete SL is a self-leveling polyurethane concrete Key Features of...

-

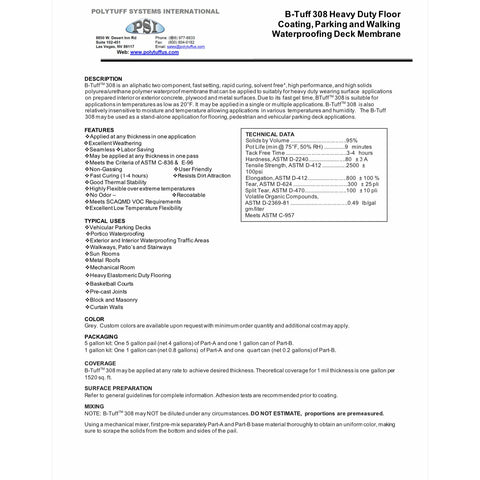

B-Tuff 308 Heavy Duty Floor Coating, Parking and Walking Waterproofing Deck Membrane 4.5 Gal kit$570.00B-Tuff 308 Heavy Duty Floor Coating, Parking and Walking Waterproofing Deck Membrane 4.5 Gal kit ...

-

TREMproof® 250GC Single-Component, Rapid Curing, Fluid-Applied Elastomeric Waterproofing Membrane$390.00TREMproof® 250GC Single-Component, Rapid Curing, Fluid-Applied Elastomeric Waterproofing Membra...

-

B-TUFF® 302 NG Single Component Solvent-Free Basecoat for Concrete, Plywood and Metal$300.00B-TUFF® 302 NG Single Component Solvent-Free Basecoat for Concrete, Plywood and Metal B-Tuff® 302...

-

Eco-HTS™ 100$350.00Tennant’s Eco-HTS 100 (High Traffic System) is a low odor/low VOC, durable, chemical resistant,...