Chemical Resistant Urethane ( CRU ) Resintech

TECHNICAL DATA

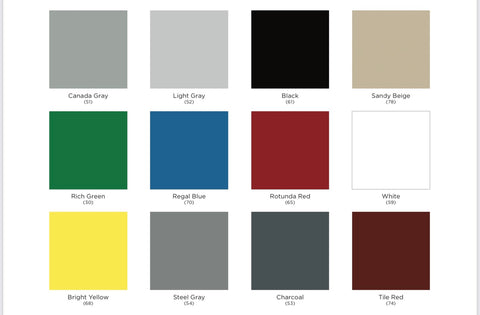

CRU is a two-component, abrasion-, chemical-, and stain-resistant, UV-stable aliphatic polyester polyurethane finish coat. It is available in clear gloss, clear satin, and can be pigmented. It is VOC compliant in all states and provinces in North America.

This urethane can be installed at thicknesses ranging from 5 to 20 mils, making it highly versatile for a wide range of applications. It can also be used as a top coat over flake floor systems, serving as a durable alternative to polyaspartic. Unlike polyaspartic, CRU offers more working time and increased durability, making it ideal for installers seeking both performance and flexibility.

CRU cures to an inert, tough, impact-, abrasion-, and chemical-resistant finish. It resists Skydrol, Betadine, and conventional hot-tire staining and provides excellent adhesion to the TUE epoxy system. When applied to properly prepared concrete or cementitious overlays, it requires a Polyurethane-Acrylic Primer and Concrete Sealer for optimal performance.

It is widely used as an upgraded finish coat in Canopus coating systems for:

- Aircraft hangars

- Industrial kitchens

- Automotive showrooms and shop floors

- Commercial laboratories and research facilities

- Hospitals and healthcare environments

- Wine and spirit processing facilities

- Any surface exposed to heavy foot traffic, forklift movement, or chemical exposure

ADVANTAGES

- Long pot life

- Respectable odor

- Superior chemical resistance

- Excellent UV stability and gloss retention

- VOC compliant

WHERE TO USE

- UV-stable top coat

- Aircraft hangar floors

- Production areas

- Maintenance facilities

- Warehouses

IMPORTANT NOTE: PROPERTIES @ 73°F (23 °C) and 50% R.H. Times are approximate and will be affected by changing ambient conditions, especially changes in temperature and relative humidity. The indicated mileage is calculated for flat surfaces. A porous or imperfect surface will require more material in order to cover the same mileage.

| PACKAGING | 1.6 US gal (6 L) |

| COVERAGE RATE | 800 ft2/kit |

| RECOMMENDED THICKNESS | 3.2 wet mils (81 microns) |

| MIX RATIO, BY VOLUME | A:B = 2:1 + .4 lb Aluminum Oxide |

| DENSITY (KG/L) | Part A: 4L Part B: 2L Mixed: 6.4 L |

| POT LIFE | 60 minutes @ 77°F (25°C) |

| WORKING TIME | 30 minutes |

| VOC | 75.4 g/L |

Have Questions? Ask An Expert

Related Products

From this Collection

-

Universal Pigment Pod$35.55Universal Pigment Pod Universal Pigment Pods are pigment that are fully compatible with the 100% ...

-

ResinTech UV Resistant TRANSPARENT UNIVERSAL EPOXY 100% SOLIDS ( TUE ) 15L - 4 Gals$325.00ResinTech TUE (Transparent Universal Epoxy) Specification Product Overview: ResinTech TUE (Transp...

-

EPOXY ROLL PRO Refill$13.99EPOXY ROLL PRO Refill Features: Solvent Resistant PVC Core Epoxy Bonded EPOXYROLL PRO roller...

-

ResinTech High Performance Polyaspartic ( HPP ) 10 L / 2.64 Gal$340.00Product DESCRIPTION HPP is a fast-curing, two-component Polyaspartic floor coating system engine...

-

Paint Roller Sleeves$4.99Paint Rollers Cover, 9 X 1.5inch - 18 X 1.5inch - 4 inch 10mm (10 Packs) Roller Cover Material:...

-

Nitrile Gloves$21.99Nitrile Gloves Size : M, L, XL 100 Gloves BLACK NITRILE POWDER FREE LATEX FREE NON-STERILE MU...

-

XYLENE$34.90Reducer No. 4 (XYLENE) Use exclusively for thinning industrial maintenance coatings. 3.78...

-

Canoflake 3/8'' Blend Flake System (55 LBS/Box)$18.00Canoflake 3/8'' Blend Flake System (55 LBS/Box) Blend Flakes are designed to use with the concre...

-

Silica Abrasives Sand$25.00Silica Abrasives are high quality, close graded silica sands which are produced at our Morinville...

-

Spike shoes (Adjustable)$14.99Spike shoes Spike shoes for installing self leveling and floor coating projects. Strap Shoes : ...

-

5/16 Plastic Cap for 18'' Refill$1.005/16 Plastic Cap for 18'' Refill Multiple flexible ribs ensure easy install and secure fit. Dura...

-

Rags (100% COTTON)$21.98CANOPUS POLO COLOURED Rags (100% COTTON) Polo Coloured wipers are soft, low in lint and hight in ...

-

Metallic Epoxy Pigments$49.99Metallic Epoxy Pigments metallic collection 🔹AppleGreen🔸AztecGold🔹BlackPearl🔸Bronze-Brown...

-

Dymonic® 100 High-Performance, High-Movement Single-Component, Polyurethane Sealant$11.00Dymonic® 100 High-Performance, High-Movement Single-Component, Polyurethane Sealant Basic Uses ...

-

Squeegee Trowel$33.95Squeegee Trowel Features: Trowel smoother with flexible rubber blade Threaded handle Multi-...

-

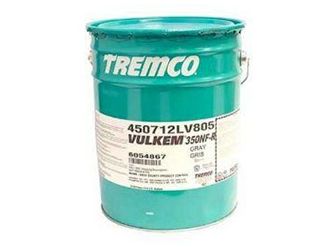

Tremco Vulkem 350NF Base Coat$398.00Single-Component, Low Odour, Low VOC, Urethane Membrane Vulkem® 350NF Base Coat is a single-com...

-

Mixing Cup 5 US QT$5.505 Gallon Pail - Metal Handle 5 US QT capacity Keywords:🔸 Where to buy Bucket, Measure paint, ...

-

Roller Handle$2.95Keywords:🔸 Where to buy drywall, for small tiles, heavy duty, Nour product, Nour online catal...

-

Wooster 18 in. Big Ben Roller Frame$34.99Wooster Big Ben Roller Frame is sturdy and made of rust-free, easy-to-clean polypropylene. The le...

-

6 Gallon Pail - Plastic Handle$6.496 Gallon Pail - Plastic Handle One gallon capacity Lid available Reinforced lip Durable construc...

-

CANTECH STUCCO TAPE 1.88"x60YD RD$12.99CANTECH STUCCO TAPE 1.88"x60YD RD Delivers sharp paint lines Removes cleanly with no residue...

-

Putty Knife$4.99Putty Knife, 4inch Stainless steel blade PP+TPR soft grip handle Keywords:🔸 Where to buy w...

-

23" Economy Tray$5.9523" Economy Tray R TL850 - Tray Liner R TR850 - Tray 23 inch tray (2L capacity) is made of rec...

-

Thin Throwaway Brush$0.99Thin Throwaway Brush Features: One-use throwaway brush For cost-conscious consumer Great for...

-

5 Gallon Pail - Metal Handle$5.995 Gallon Pail - Metal Handle One gallon capacity Lid available Reinforced lip Durable constructi...

-

Canopus Redi Lock Diamond Tool$45.00Redi lock concrete grinding diamond pads ✔️For Grinding and polishing concrete floors. Keywords...

-

Aliphatic Top Coat Urethane (TCU) Resintech ( Satin / Matte Finish )$340.00TCU is a two-component abrasion, chemical and stain resistant, UV stable aliphatic polyeste...

-

Sausage Gun$28.98Sausage Gun 15 in, 600 ml Dispenses caulking, adhesive and sealant from a standard cartridge o...

-

PAINTERS MATE TAPE GREEN$3.99PAINTERS MATE TAPE GREEN PAINTERS MATE GREEN MASKING TAPE Use with all paints, most lacquer...

-

Vulkem 346 Top Coat Aliphatic one-component polyurethane$430.00Vulkem 346 Top Coat is an aliphatic one-component polyurethane that is applied after the Vulkem ...

-

MAPECEM QUICKPATCH$35.00MAPECEM QUICKPATCH High-Performance Concrete PatchMapecem Quickpatch is a high-performance, fa...

-

TAPE BLUE$9.99Paintpro TAPE BLUE Delivers sharp paint lines Removes cleanly with no residue Applie...

-

Tremco Vulkem 950NF Top Coat$424.00Vulkem 950NF Top Coat is a two-component polyurethane that is applied after the Vulkem 350NF bas...

-

TREMfloor / Flowfresh$40.00TREMfloor / Flowfresh 2 Gal kit A slurry-broadcast, cost effective and HACCP International certi...

-

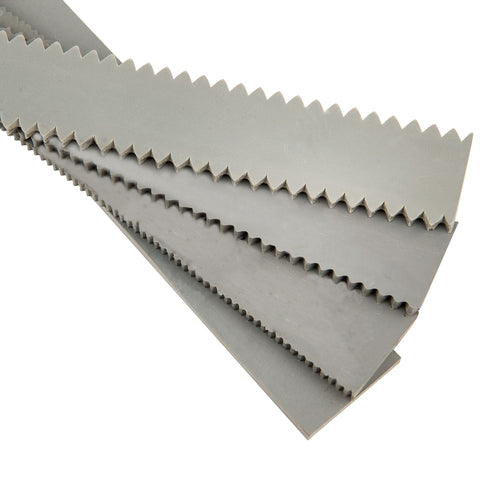

24" EPDM Rubber Blades$16.9524" EPDM Rubber Blades Features: For use with Aluminum Clamp Squeegee Ideal for all coat...

-

Diamond Polishing Pads$18.00Diamond Polishing Pads (5 Inch) For Wet and Dry Polishing Optimal RPM 2200 Max RPM 4500 Works ...

-

Cutter - 18-mm - ABS Plastic and Stainless Steel - Yellow$8.00Cutter - 18-mm - ABS Plastic and Stainless Steel - Yellow The utility knife with ratchet blade ...

-

Paint brush 2inch$3.99Paint brush 2inch Solid round filament, shiny steel ferrule Keywords:🔸 Where to buy Finch ...

-

Coating Squeegee$29.95Coating Squeegee Features: Plastic thread for extension pole attachment Solvent resistant S...

-

SQUEEGEE TROWEL$24.95Pro Frame (Comes with 2 Endcaps) Features: Made of glass infused polypropylene making roller ...

-

Cup wheel for concrete$134.00Cup Wheel Diamond Disk 7 and 5 inch 6 Arrow segments 15mm height 30 grit soft bond Central...

-

Mallory - Floor Squeegee$50.00Mallory - Floor Squeegee HEAVY- DUTY CONSTRUCTION Thick pliable Rubber blade Gray-Regular n...

-

Aluminum Clamp Squeegee$36.95Aluminum Clamp Squeegee Features: Aluminum clamp-style squeegee for easy blade removal Heavy ...

-

Wood Handles Threaded Metal Tips$10.95Nour Series, Deluxe 3 Piece Kit Z AC60M 1500 60 0-59186-74326-3 - 10 5 Keywords:...

-

ResinTech Core Bond EPOXY ( CBE ) 100% SOLIDS 15L - 4 Gals$310.00ResinTech Core Bond EPOXY 100% SOLIDS (CBE) Specification Product Overview ResinTech Core Bond ...

-

MAPECRETE HARD LI$358.00MAPECRETE HARD LI Lithium Silicate Densifier and Sealer for Concrete Mapecrete Hard LI is a wa...

-

Canopus Industrial Concrete HEPA Vacuum with Auto Filter Cleaning Function for Concrete Floor Grinders

$6,400.00$4,800.00Canopus Industrial Concrete Vacuume , is Equipped with the Auto Filter Cleaning Function for the ... -

Training Package 1$500.00Training Package 1 (Dec 17 2025) Concrete prep, Epoxy, Polyaspartic & Urethane systems, Flake...

-

Floor Squeegee$19.99Floor Squeegee Plastic connector Zink Plate or stainless steel plate Size : 65 cm or 25 inch ...